4100 Water/Soil Sample Processor

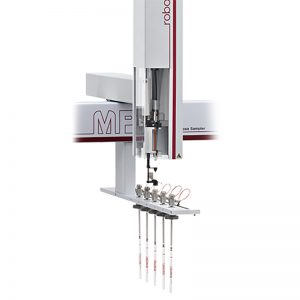

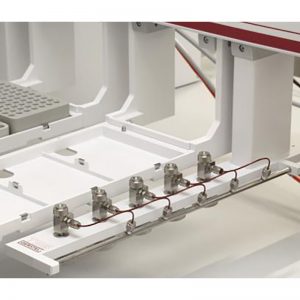

Improve sample processing reliability and analytical performance with the Model 4100 Water/Soil Sample Processor. This automated instrument is efficiently built to process up to 100 drinking water, wastewater, or soil samples.

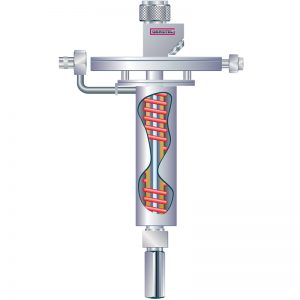

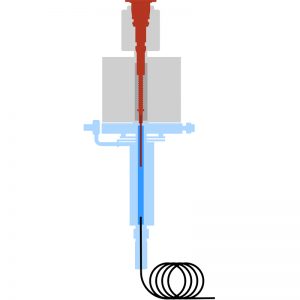

Say goodbye to handling and processing samples for purge-and-trap analysis of volatile organic compounds (VOCs). The 4100 Sample Processor is designed to operate with (single or dual) Eclipse 4760 purge-and-trap sample concentrators.