Description

Efficient and Accurate Analysis

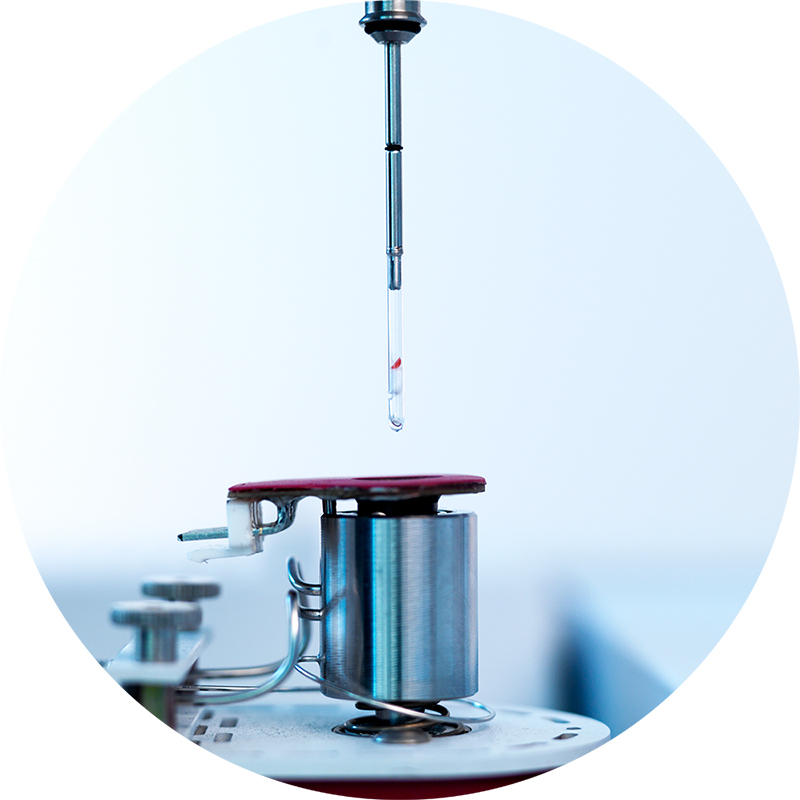

When combined with the industry standard GERSTEL MultiPurpose Sampler MPS, up to 196 samples can be pyrolyzed automatically in one batch. With just one method and one sequence table the analyst can set up the complete system including thermal desorption, pyrolysis, and GC/MS analysis. This reduces the risk of error and enables a highly efficient work-flow, while providing sensitive and reliable results. The Pyrolyzer is very easy to operate: The smple is placed in a sample holder, which is mounted onto the TDU pyrolysis transport adapter and placed in the MultiPurpose Sampler PYRO tray. The sample is then automatically inserted into the TDU Pyrolyzer. Pyrolysis break-down products are transferred directly to the GC column in split mode or refocued in the GERSTEL Cooled Injection System (CIS) before being introduced as a narrow band onto the GC column for separation. The GERSTEL PYRO can also be used for manual operation with the TDU as needed.

Wide Pyrolysis Temperature Range

PYRO performs standard pulsed pyrolysis at temperatures from 350 to 1000C. The temperature can be varied from sample to sample in order to analyze different kinds of samples in one batch; to perform sequential pyrolysis on multiple identical samples in series; or to perform fractionated pyrolysis on a single sample for more indepth information. In addition to pulsed pyrolysis, programmed heating can be specified at rates ranging from 0.02 to 100C/s. Optimal analysis conditions can be chosen for each sample type and for every conceivable matrix. A thermal desorption step can be performed in the temperature range from ambient to 350C prior to pyrolysis to purge VOCs form sample or for solvent venting.

Split Interface And Cryo Trap

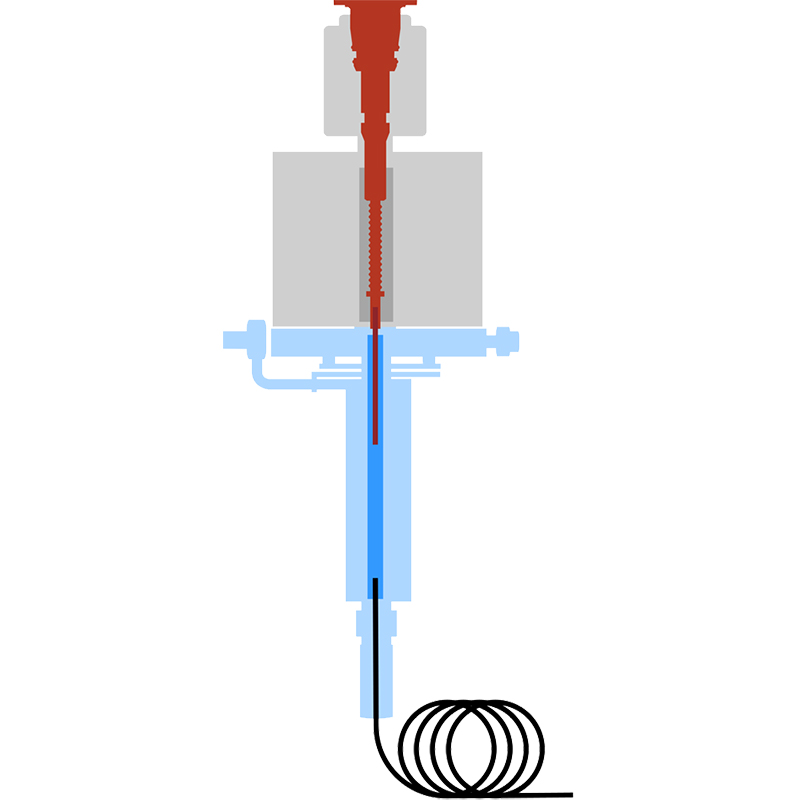

Pyrolysis breakdown products are transferred to the GC/MS system using the GERSTEL Cooled Injection System (CIS) PTV-type inlet. The CIS can be used either simply as heated split interface or as an intermediate cryofocusing trap for trace analytes.

A wide range of concentrations and sample amounts can be handled by the PYRO system while ensuring best possible recovery, excellent GC separation and maximum information content.

Low Sample-to-sample Carry-over

The valve-free liner-in-liner concept eliminates sample-to-sample carry-over and the TDU and CIS liners are heated over their entire lengths ensuring best possible recovery. Non-volatile residue is caught in the CIS liner. From there it can easily be removed after a user-defined number of analyses together with the disposable liner. The system at large is not contaminated. The platinum filament is connected using Four Conductor Technology ensuring accurate monitoring of the filament resistance and accurate temperature control delivering reliable results at all times. Change over between standard TDU operation and pyrolysis operation is performed in less than ten minutes. If the liner needs to be changed another 5 minutes are needed. The complete system including the GC/MS can be used in a highly flexible manner to the greatest possible benefit of the analyst and the laboratory.

PYRO Features and Benefits:

- Multiple pyrolysis techniques available

– Pulsed pyrolysis

– Sequential pyrolysis

– Fractionated pyrolysis

– Thermal desorption with solvent venting and pyrolysis of the same sample

– Split- or splitless operation

– Selectable cryo trapping - Efficient and reliable automation

- Dedicated optimized sample holders for liquid and solid samples

- Flexible and proven resistance heating using Pt filament provides selectable pyrolysis temperature from 350 – 1000C.

- Liner in liner system / No valve in sample flow path

- Flexible modular system

- Integrated MAESTRO software control