OBSERVER

Real-time process monitoring and control software for ultraDAWN

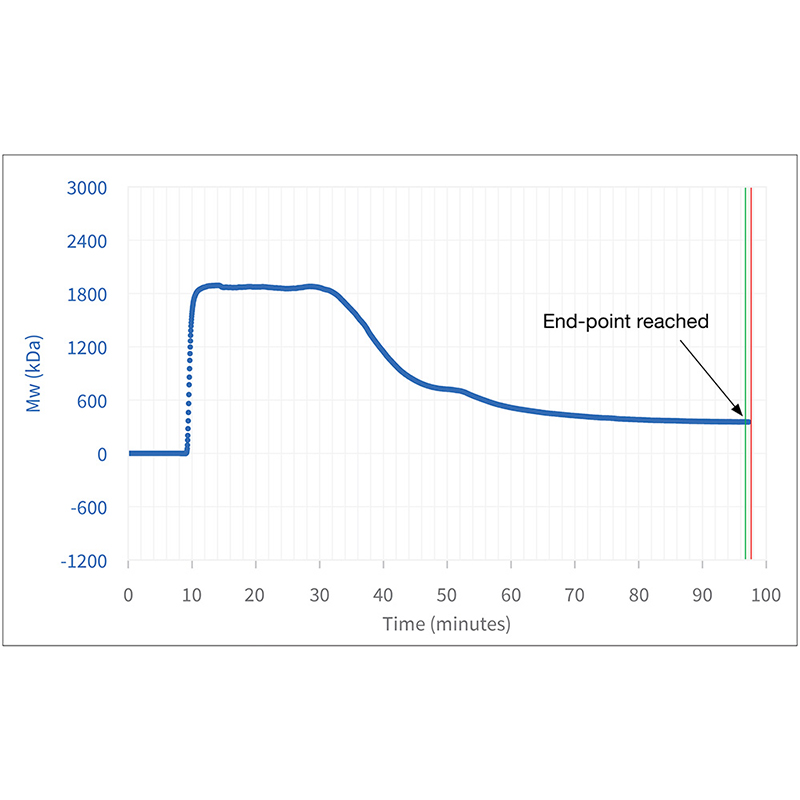

OBSERVER acquires real-time multi-angle light scattering data from ultraDAWN, then calculates and reports weight-average molar mass and z-average rms radius, thirty times each minute.

Where most PAT instruments monitor process conditions such as temperature, pressure and feedstock, OBSERVER’s RT-MALS analysis provides actual product quality attributes. When the RT-MALS results deviate from specifications or reach the process end point, OBSERVER can send a trigger to control the process, directly or indirectly via OPC.